~$

~$

Programming & Software

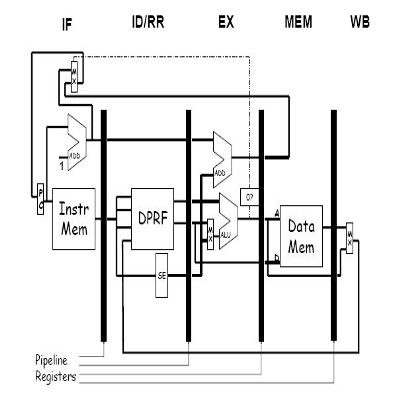

Systems & Hardware

Data & AI/Machine Learning

CAD, Design & Manufacturing

~$

Capstone Project

Machine Design Case Studies

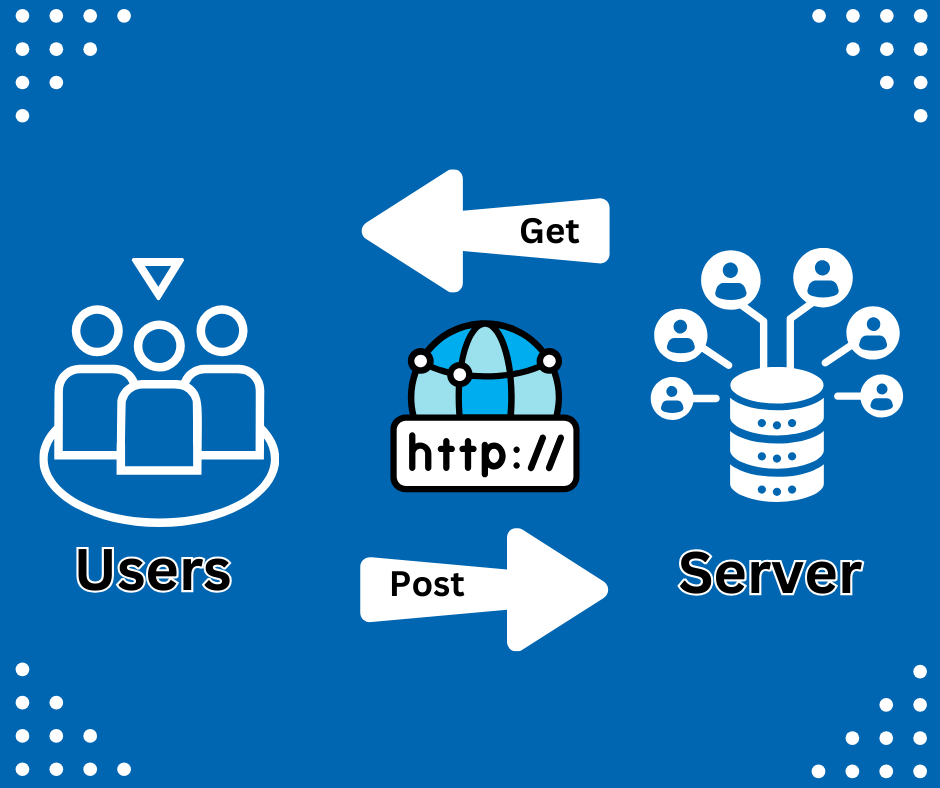

HTTP Server in Modern C++

My Portfolio Website

Recession Predictor Project

Systems Programming Projects

Machine Learning Projects

Robotics Coursework

Intro to AI Projects

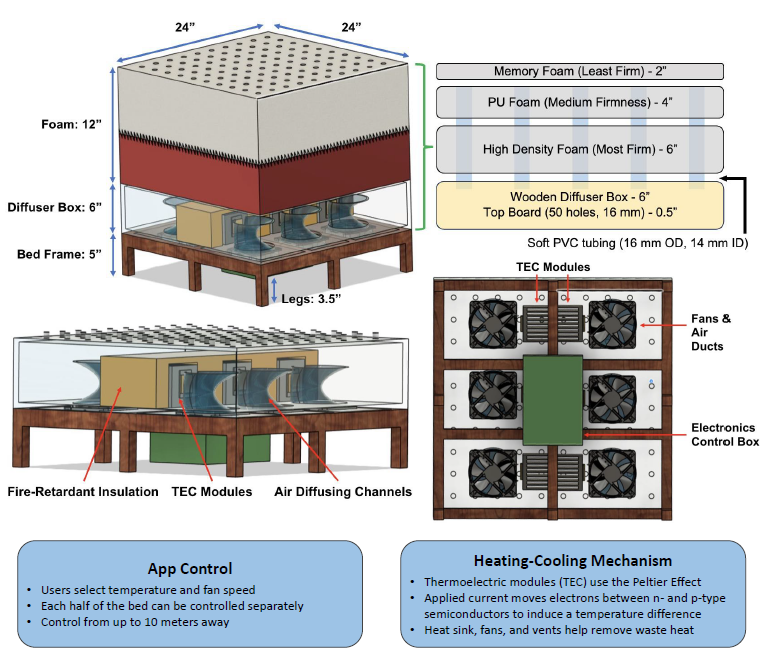

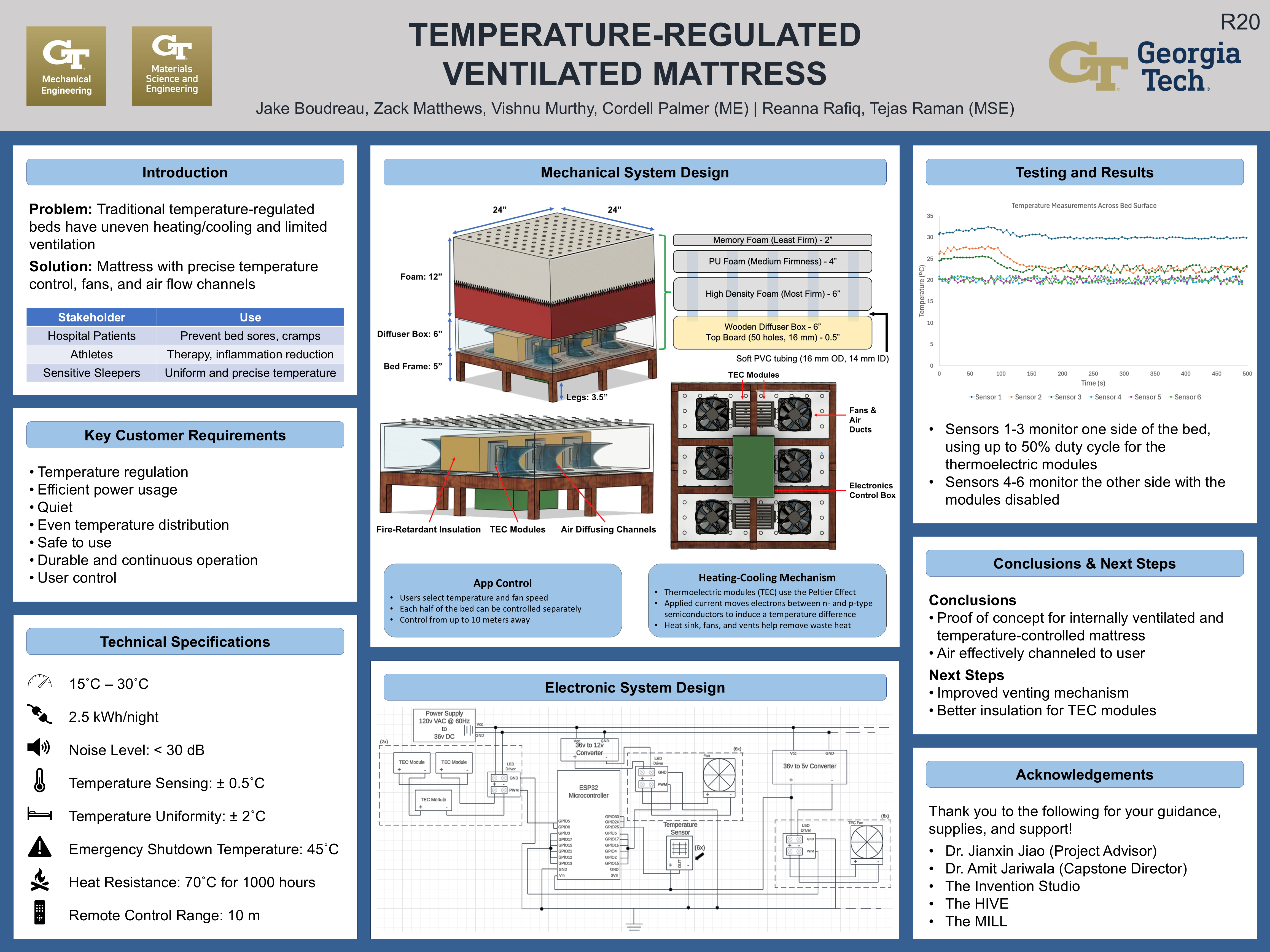

Temperature-Regulated Ventilated Mattress

I led the complete electronics design and integration for our heating/cooling smart bed, including full electrical assembly, sensor integration, and software control system development. For more detailed images of my contributions and full technical documentation, see the final report above.

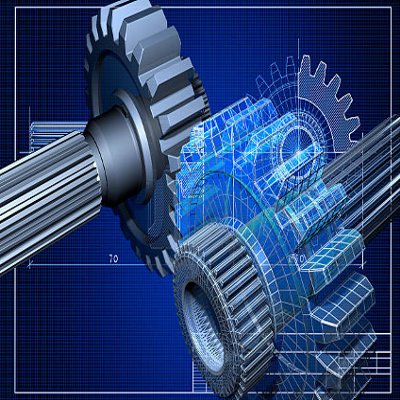

Machine Design: Chop Saw Analysis

Overview

Machine Design at Georgia Tech (ME 3180) is widely regarded as being a notoriosuly difficult, but highly rewarding class. It’s taught by a professor who’s both respected and feared in the best way — pushing students to really understand how mechanical systems behave under load rather than just memorize formulas.

Lectures equipped us with the theory of design analysis: contact stress, Von Mises failure criteria, fatigue, and how real parts like bearings, gears, shafts, and fasteners hold up under stress. It built on deformable bodies but at a much higher level, forcing us to think critically about how systems fail and how to design against it.

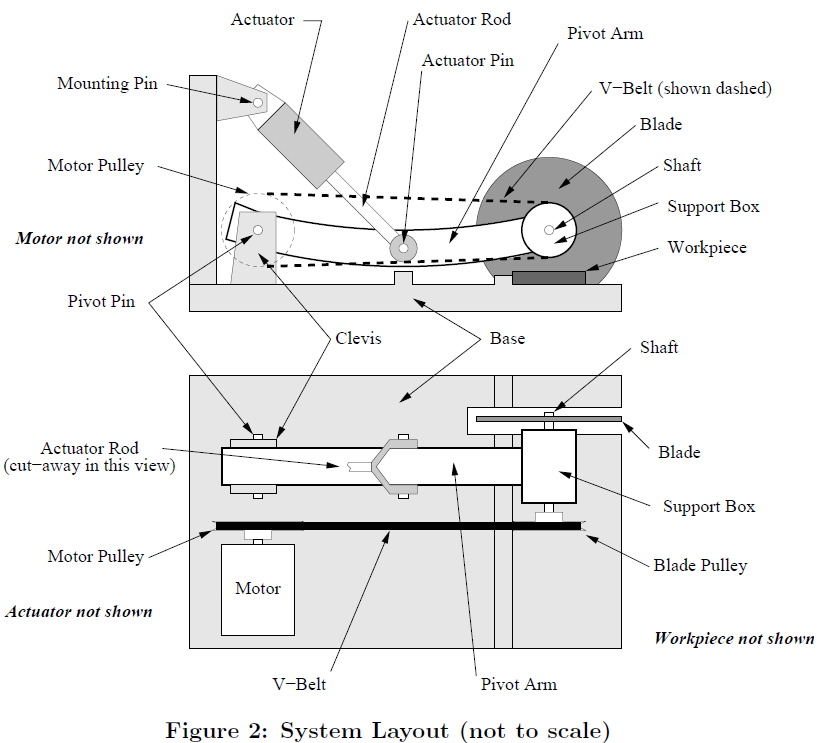

The course featured three major design projects, each lasting several weeks. We tackled the force design of a chop saw in stages — first the chassis, then fastener forces, and finally gears. These projects demanded long days of calculations, writing detailed reports, and constant trips to office hours. Collaboration with classmates was almost a requirement to make it through.

As draining as it was, the class sharpened my ability to break down complex force problems, document work clearly, and think like an engineer who’s designing for failure as much as for function. It was easily one of the hardest classes I took, but also one of the most valuable.

Design Problem 1: Chop Saw Armature

Pivot Arm Static Design

- Drafted an initial model of all acting static forces on the chop saw armature.

- Applied contact stress and Von mises to identify and examine weak point magnitudes.

- Wrote a MATLAB script to quickly update calculations based on adjusted input parameters.

- Collaborated with a small team to complete a full technical report.

Results: Certainly wasn't our best project, but lessons learned here applied toward a much stronger performance in subsequent, individual-based design problems.

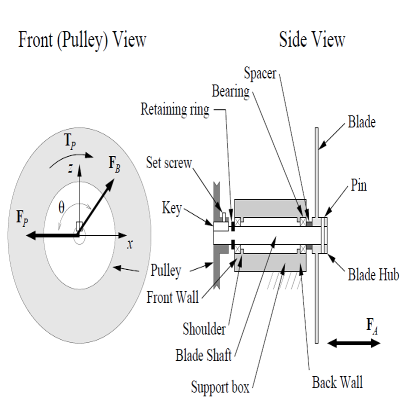

Design Problem 2: Chop Saw Blade Shaft Design

Shaft Design & Loading

- Designed the chop saw blade shaft and its connection components (key, set screw, pin, retaining ring).

- Developed a force model of all static loads acting on the rotating shaft assembly.

- Applied Von Mises and cyclic loading fatigue analysis to identify high-stress regions and potential failure points.

- Built a MATLAB script to parameterize calculations and automate updates for material and dimension changes.

- Created a CAD model of the final design located in the report.

Results: Scored 81% on the overall submission.

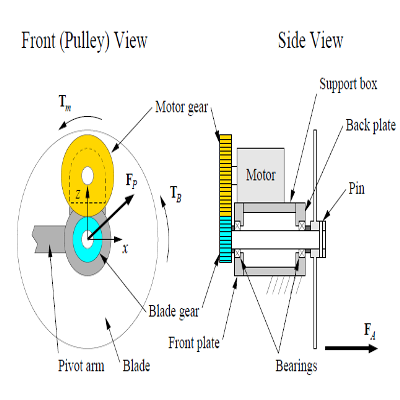

Design Problem 3: Chop Saw Blade Shaft Bearings and Gear Design

Bearings and Gear Loading

- Designed and selected gears and ball bearings for blade shaft torque transmission.

- Designed the gear train kinematics according to the problem constraints.

- Determined static and dynamic load rating for blade shaft bearings.

- Determined forces acting on the gear teeth (radial, tangential, axial).

- Built a MATLAB script to parameterize calculations and automate updates for material and dimension changes.

- Created a CAD model of the final design located in the report.

Results: Scored 95% on the overall submission.

~$

Email📧

cordell.palmer41@gmail.com

https://www.linkedin.com/in/cordell-a-palmer/

GitHub

https://github.com/engineercordell